Super Tiny Jet Dispenser

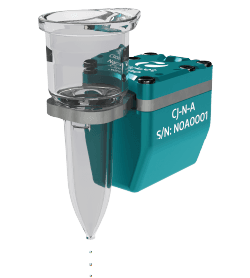

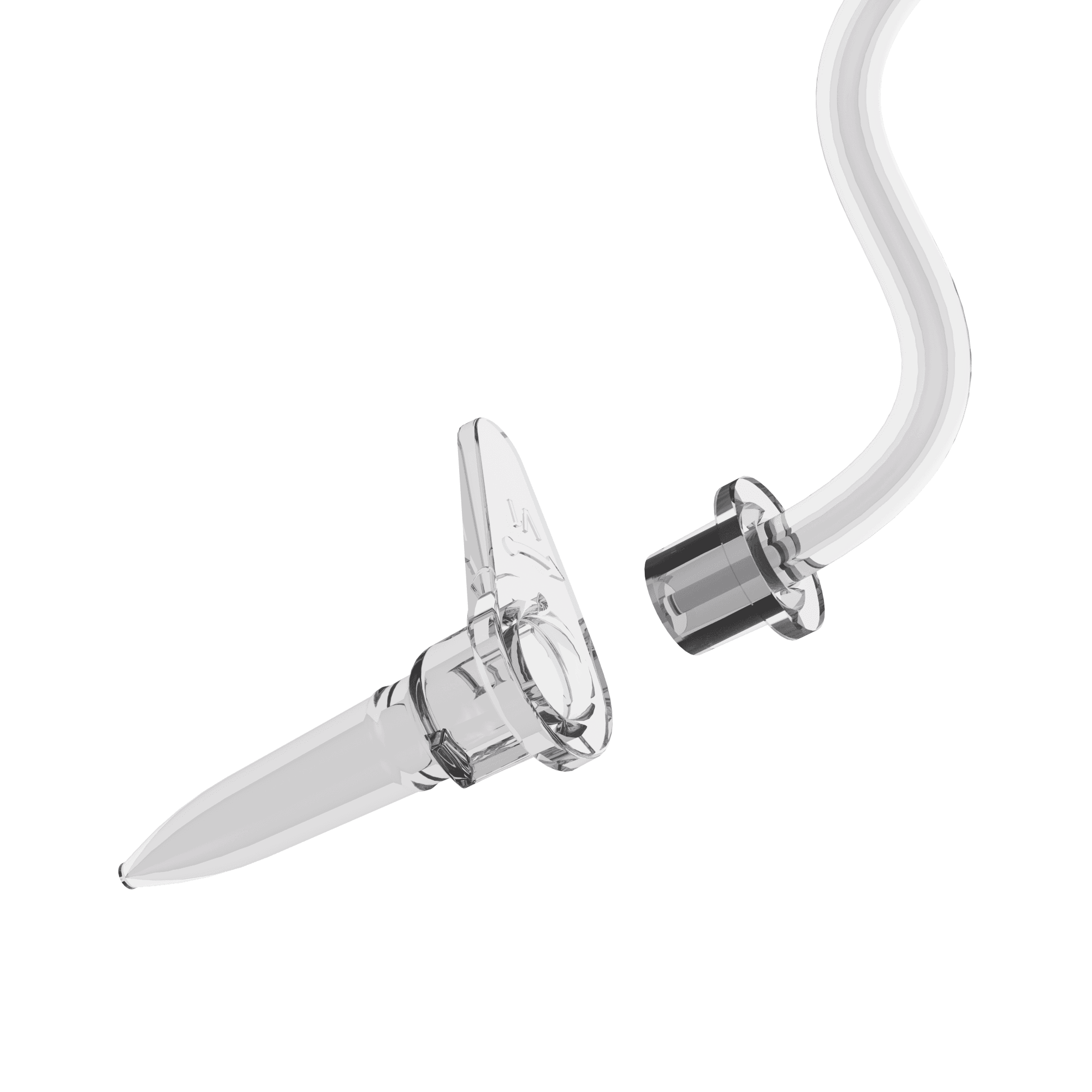

ClickJet

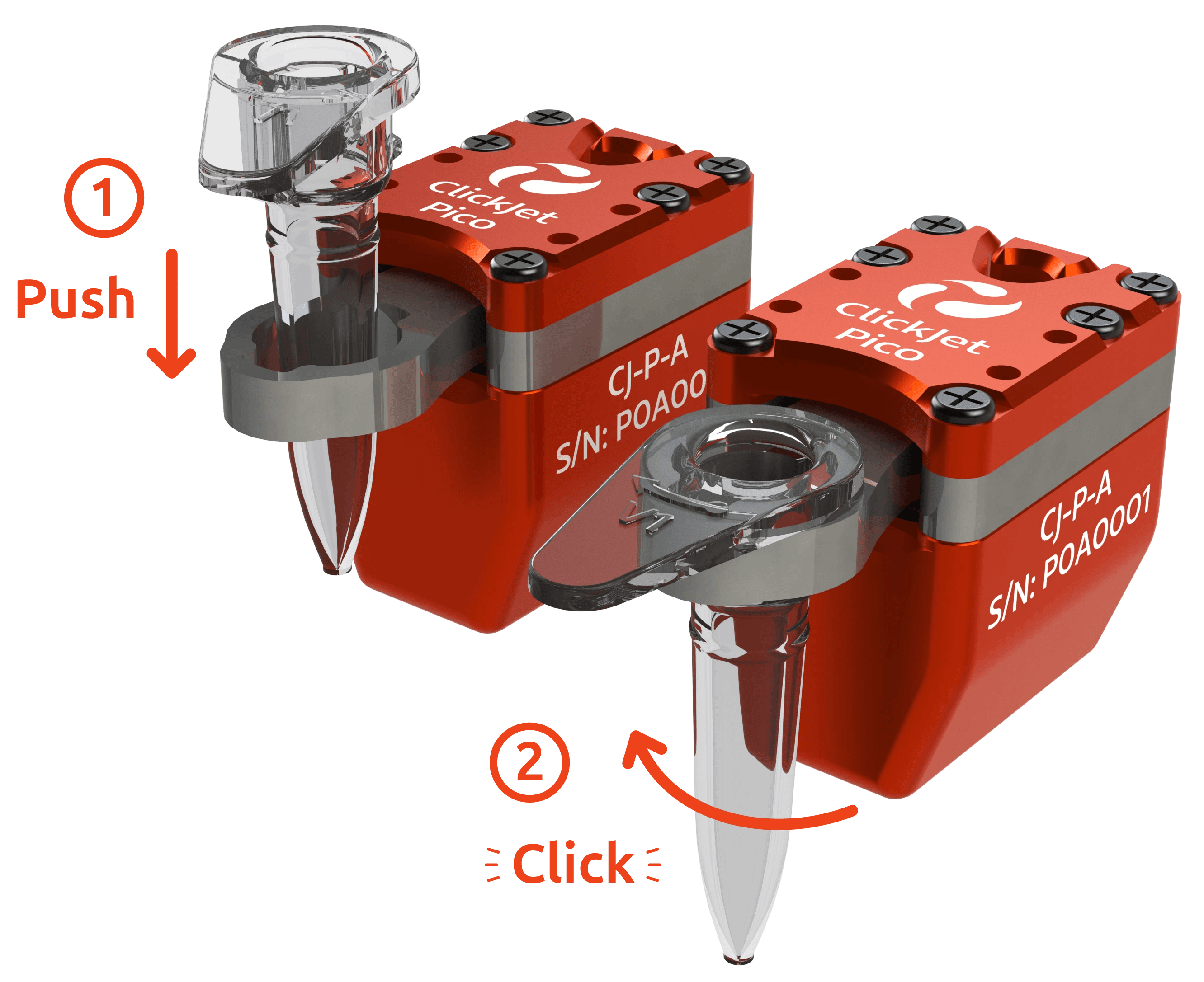

The ClickJet Jet Dispenser for contactless dispensing in the nanoliter and picoliter range combines maximum precision with a small form factor and intuitive operation. The nozzle with integrated liquid reservoir can be changed with just one click.

Two jet dispensers - two innovations:

ClickJet-Pico and ClickJet-Nano

Suited for a wide range of industries

Our ClickJet system is also highly versatile and can be adapted for many other applications. If your industry isn't listed here, please contact us to discuss how our technology can meet your specific needs.

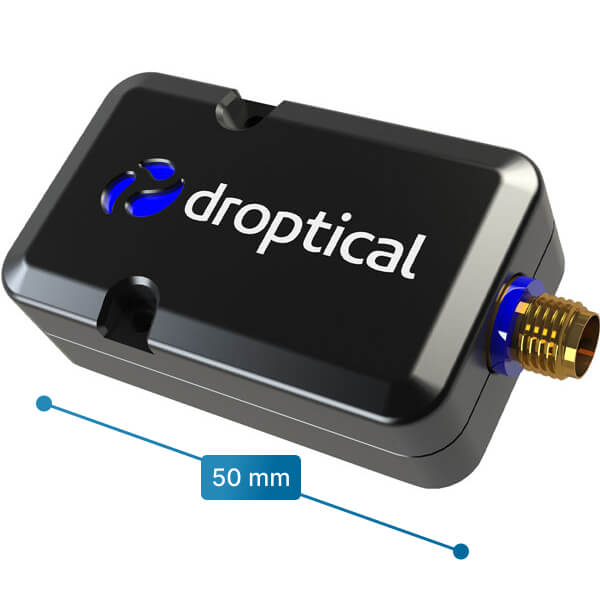

Cutting-Edge Micro Dispensers: Innovation in every Drop

Introducing our precise miniature contacless dispensing solution, designed to meet the highest standards of accuracy and efficiency and usability in product dispensing. Our solution ensures minimal waste and maximum productivity. With our innovative actuator principle, we are setting new standards and enabling precise dosing and positioning of even the smallest quantities of fluids with incredible efficiency.

Time-saving

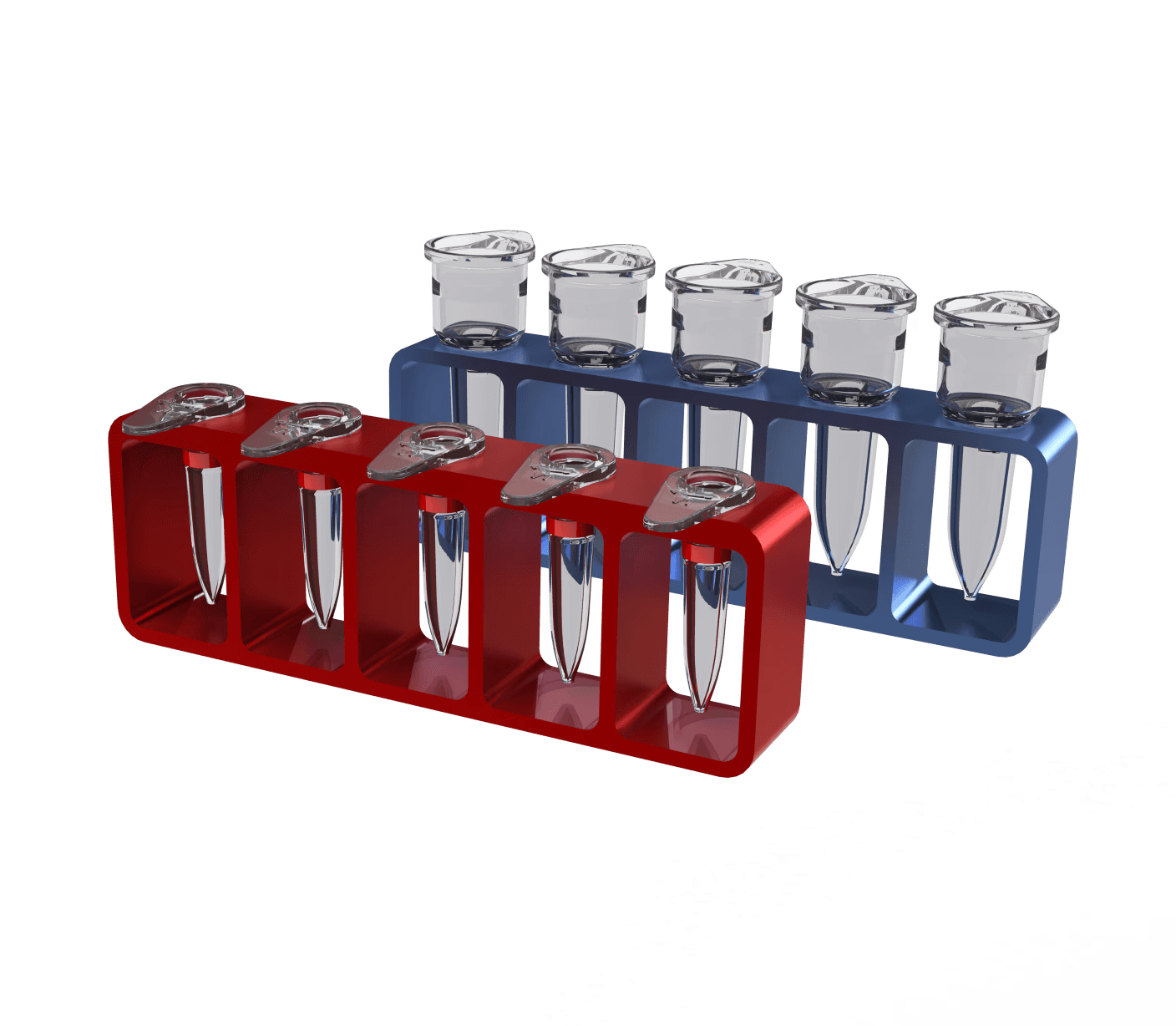

The ClickJet family has interchangeable nozzles with an integrated cartridge. These can be filled or replaced extremely quickly. Dirty nozzles can be cleaned or disposed of cost-effectively. The process only needs to be interrupted for a few seconds.

Sustainability

Changing liquids only requires a small twist. Time-consuming cleaning and rinsing processes are not necessary. Any remaining liquid in the cartridge can simply be reused later. This saves time, money, and resources by reducing cleaning and waste.

Process Optimization

The ClickJet offers outstanding precision. The dosing is adjusted using just one parameter. This enables every operator to set up a perfect process and correct any deviations caused by environmental influences.

Usability

The ClickJet system is made of just three parts that are put into operation via plug-and-play. No software installations or complicated parameters are required. This concept allows the operator to set up the dispensing processes in an intuitive and convenient way.

Get detailed Specs for the ClickJet system

We are pleased to provide you with comprehensive technical specifications. Please contact us using the contact form below. You will receive the complete PDF with detailed information on all the functions and benefits of our system.

Accessoires

Get in Touch

You can reach us anytime via sales@droptical-systems.com